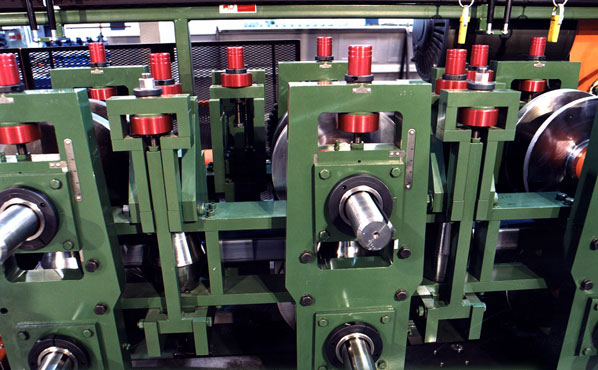

Roll Forming Line

MMC Roll Forming Lines can be set up with multiple configurations to punch and cut off parts in a continuous operation generally integrated with cut to length Lines for cutting formed part to length in pre cut or Post cut operation. The lines can be set up to use a pre-cut die where a single blank runs through the roll mill, or a post-cut die where the profile is cutoff after the roll forming process.

Additional Features may be added in the line for hole punch, notch, embossment, or shear form by punching in a roll forming line. These features can be done in a pre-punch application (before roll forming starts), in a mid-line punching application (in the middle of a roll forming line/process) or a post punching application (after roll forming is done).

MMC roll forming machines can produce any geometric shapes of different sizes and material thicknesses up to 9mm in Cold drawn Stainless or Carbon Steel.

We offer high speed Roll forming lines for Galvanized / Pre Painted coils upto 1450mm input width as well as very heavy gauge forming Lines operating at lower speed.

MMC also undertakes replacement, refurbishing and redesigning the old Roll Forming plants to suit the updated application accommodated at the existing site conditions. Automatic and semi-automatic machine have been deployed at several installations. All these equipment are newly designed one of it’s kind and working satisfactorily since commissioned.